How To Easily Describe Your Kickoff Cyclohexane Chair Using the "Parallelogram Technique"

Now that we've had an aerial tour of the cyclohexane chair, nosotros're going to movement on to a very important skill:how to properly draw 1 of these beasties.

There are several techniques for properly draw a cyclohexane chair.

In this video, I walk through what I consider to be the most completely idiot-proof way to draw a chair, by first drawing a parallelogram (something you should already know how to do). Using this as the "base" of our chair, nosotros then describe flaps moving up and down (representing the caput and footrest), then put in the axial and equatorial groups.

Importantly, we tin use this method to describe a chair in either the "left mitt" or the "right mitt" version of a cyclohexane chair, which becomes important, one time we learn about chair flips (that'south next!)

In time and with a little bit of practice, you won't need to draw the parallelogram to guide you. Think of it as a set of training wheels that you will afterward discard once you don't demand them anymore.

How NOT To Draw The Cyclohexane Chair Conformation: 4 Examples

Having an easy-to-think technique is crucial.

Otherwise, your kickoff few attempts in drawing a cyclohexane chair from retentivity might see you stop up with one of these "variations" from a rogue'due south gallery of four ways to spiral up drawing a cyclohexane chair (and don't feel bad – we've all done it . The trick is to make all the necessary mistakesbefore y'all take your midterm).

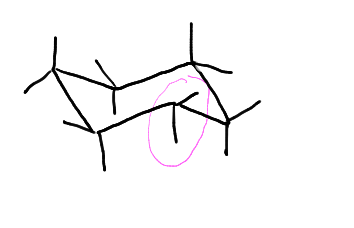

Bad Cyclohexane Chair #1: Crow'due south Pes

| What'due south incorrect? The axial and equatorial positions on the circled carbon are fatigued in the incorrect direction, leading to the carbon having a "crow's foot" appearance. Bond angles in this carbon is not properly tetrahedral – furthermore, the next carbons are eclipsed, non staggered! How to fix:Flip the groups on the carbon. The "axial down" group should exist drawn as "centric up" and the "equatorial up" group should be drawn equally "equatorial downwards". Think, the axial groups alternate "upward, down, up, down, upward downwards" throughout the ring. |

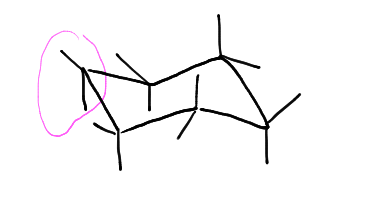

Bad Cyclkohexane Chair #2: Crow's Foot (slight return)

| What's wrong?Some other crow'due south foot, although drawn on the "caput rest" of the chair. How to set up:switch "axial downward" to "axial upward" and "equatorial upward" to "equatorial downward". And then y'all'll come across that your axial groups now alternating up downwards up downward upwards downwards again (similar they should) |

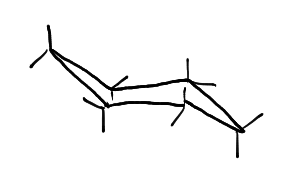

Bad Cyclohexane Chair #3: "The Lightning Bolt" [h/t Chemjobber]

| What'south wrong?The axial and equatorial positions are drawn in properly, but the chair is fatigued and then thinly that the forepart carbons obscure the groups on the dorsum carbons. How to fix: The angles at the "headrest" and "footrest" are too acute; open up them up a bit. Also, stagger the two front carbons and the 2 back carbons so that they're not straight in front of each other. |

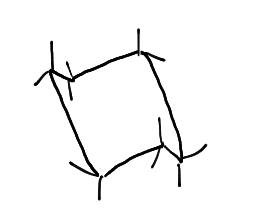

Bad Cyclohexane Chair #iv: "Mr. Fatty"

| What's wrong?Though all the centric and equatorial positions are drawn properly, this diagram strains the imagination for a cyclohexane supposedly consisting of six equal sides. How to fix:Pretty straightforward – only don't draw the vertical bonds so long! |